Elastic sleeve-finger coupling GOST-21424-93

Couplings of general machine-building application for connection of coaxial shafts for transmission of torque from 6.3 to 16000 Nxm and reduction of dynamic loads at angular, radial and axial displacements of shafts. Parameters and dimensions of couplings correspond to GOST 21424 elastic sleeve-finger couplings.

Further information on gearbox dimensions, shafts, gear ratios, etc. can be found in the catalogue.

Operating Conditions:

- operation for long periods of up to 24 hours a day or with occasional stops;

- rotation speed not exceeding the value specified in the technical data table;

- spinning in either direction;

- climatic versions - У1, У2, УЗ, УХЛ-4, Т1, Т2, ТЗ and О4 according to GOST 15150.

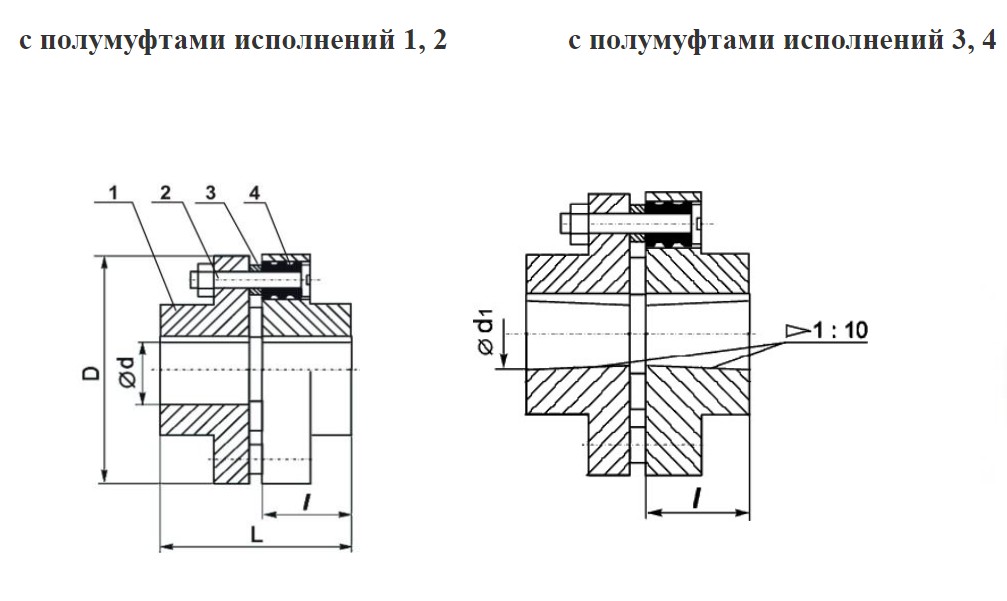

Notation:

Tkr - nominal torque, N x m

d - diameters of bushing seating holes or holes of bushings and flanged coupling halves

Isp - bushing designs:

1 - with cylindrical holes for long shaft ends according to GOST 12080;

2 - with cylindrical holes for short shaft ends according to GOST 12080;

3 - with conical holes for long shaft ends according to GOST 12081;

4 - with conical holes for short shaft ends according to GOST 12081.

|

Coupling number |

Rated torque

Tkr, N´m |

d

H8 |

d1

H9 |

d

H8 |

d1

H9 |

D, max. |

L, not more, for

executions |

l, h14, not more, for

executions |

Rotational speed

, с-1, no more |

Weight, kg |

||||||

| Row 1 | Row 2 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | |||||||

|

MUWP-1 |

6,3 |

9 | - |

71 |

43 | - | 43 | - | 20 | - | 13 | - |

147 |

0,58 | ||

| 10 | - | 49 | 43 | 49 | - | 23 | 20 | 16 | - | 0,60 | ||||||

| 11 | - | 0,59 | ||||||||||||||

|

MUWP-2 |

16,0 |

12 | - |

75 |

63 | 53 | 63 | - | 30 | 25 | 20 | - |

127 |

0,70 | ||

| 14 | - | 0,68 | ||||||||||||||

| 16 | - | 83 | 59 | 83 | 59 |

40 |

28 |

30 |

18 |

0,75 | ||||||

|

MUWP-3 |

31,5 |

16 | - |

90 |

84 |

60 |

84 |

60 |

106 |

1,52 | ||||||

| 18 | - | 1,40 | ||||||||||||||

| - | 19 | 1,38 | ||||||||||||||

|

MUWP-4 |

63,0 |

20 | - |

100 |

104 |

76 |

104 |

76 |

50 |

36 |

38 |

24 |

95 |

2,02 | ||

| 22 | - | 2,04 | ||||||||||||||

| - | 24 | 1,96 | ||||||||||||||

|

MUWP-5 |

125,0 |

25 | - |

120 |

125 | 89 | 125 | 89 | 60 | 42 | 44 | 26 |

77 |

3,97 | ||

| 28 | - | 4,13 | ||||||||||||||

| - | 30 |

165 |

121 |

165 |

121 |

80 |

58 |

60 |

38 |

4,37 | ||||||

|

MUWP-6 |

250,0 |

32 | - |

140 |

63 |

5,91 | ||||||||||

| - | 35 | 6,21 | ||||||||||||||

| 36 | - | 6,25 | ||||||||||||||

| - | 38 | 6,28 | ||||||||||||||

| 40 | - |

225 |

169 |

225 |

169 |

110 |

82 |

85 |

56 |

63 |

6,63 | |||||

| - | 42 | 6,86 | ||||||||||||||

| 45 | - | 6,80 | ||||||||||||||

|

MUWP-7 |

500,0 |

40 | - |

170 |

60 |

11,75 | ||||||||||

| - | 42 | 12,10 | ||||||||||||||

| 45 | - | 12,60 | ||||||||||||||

|

MUWP-8 |

710,0 |

45 | - |

190 |

226 |

170 |

226 |

170 |

110 |

82 |

85 |

56 |

50 |

14,31 | ||

| - | 48 | 14,70 | ||||||||||||||

| 50 | - | 15,21 | ||||||||||||||

| - | 55 | 15,34 | ||||||||||||||

| 56 | - | 15,22 | ||||||||||||||

|

MUWP-9 |

1000,0 |

50 | - |

220 |

18,87 | |||||||||||

| - | 55 |

48 |

19,91 | |||||||||||||

| 56 | - | 19,75 | ||||||||||||||

| - | 60 |

286 |

216 |

286 |

216 |

140 |

105 |

107 |

72 |

21,93 | ||||||

| 63 | - | 26,09 | ||||||||||||||

| - | 65 | 28,65 | ||||||||||||||

| - | 70 | 29,81 | ||||||||||||||

|

MUWP-10 |

2000,0 |

63 | - |

250 |

288 |

218 |

288 |

218 |

140 |

105 |

107 |

72 |

38 |

31,98 | ||

| - | 65 | 31,64 | ||||||||||||||

| - | 70 | 34,65 | ||||||||||||||

| 71 | - | 34,48 | ||||||||||||||

| - | 75 | 35,06 | ||||||||||||||

| 80 | - |

348 |

268 |

348 |

268 |

170 |

130 |

135 |

95 |

36,07 | ||||||

| - | 85 | 38,45 | ||||||||||||||

| 90 | - | 40,03 | ||||||||||||||

|

MUWP-11 |

4000,0 |

80 | - |

320 |

350 |

270 |

350 |

270 |

30 |

66,71 | ||||||

| - | 85 | 69,01 | ||||||||||||||

| 90 | - | 71,61 | ||||||||||||||

| - | 95 | 74,11 | ||||||||||||||

|

MUWP-12 |

8000,0 |

100 | - |

400 |

432 |

342 |

432 |

342 |

210 |

165 |

170 |

125 |

24 |

132,68 | ||

| 110 | - | 140,88 | ||||||||||||||

| - | 120 | 145,58 | ||||||||||||||

| 125 | - | 142,98 | ||||||||||||||

|

MUWP-13 |

16000,0 |

- | 120 |

500 |

435 | 345 | 435 | 345 |

19 |

237,81 | ||||||

| 125 | - | 234,61 | ||||||||||||||

| - | 130 |

515 |

415 |

515 |

415 |

250 |

200 |

205 |

155 |

264,31 | ||||||

| 140 | - | 264,61 | ||||||||||||||

| - | 150 | 356,31 | ||||||||||||||

| 180 | - | 615 | 495 | 615 | 495 | 300 | 240 | 245 | 185 | 308,11 | ||||||

Example of designation : Elastic sleeve-finger coupling MUVP - 7 - 500 - 40 - 1 - 45 - 4 U3: sleeve-finger coupling with a rated torque of 500 N x m, one sleeve with a diameter of the seating hole 40 mm, version 1, the other with a diameter of 45 mm, version 4, climatic version U and placement category 3.

Attention: We can produce special gear couplings with diameters different from the standard ones. Please specify the required nominal torque Tkr and the required overall and connection dimensions.

1 - coupling half; 2 - pin; 3 - spacer bushing; 4 - elastic bushing.