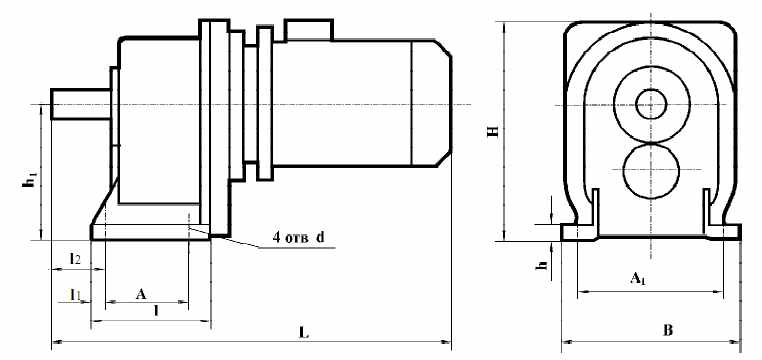

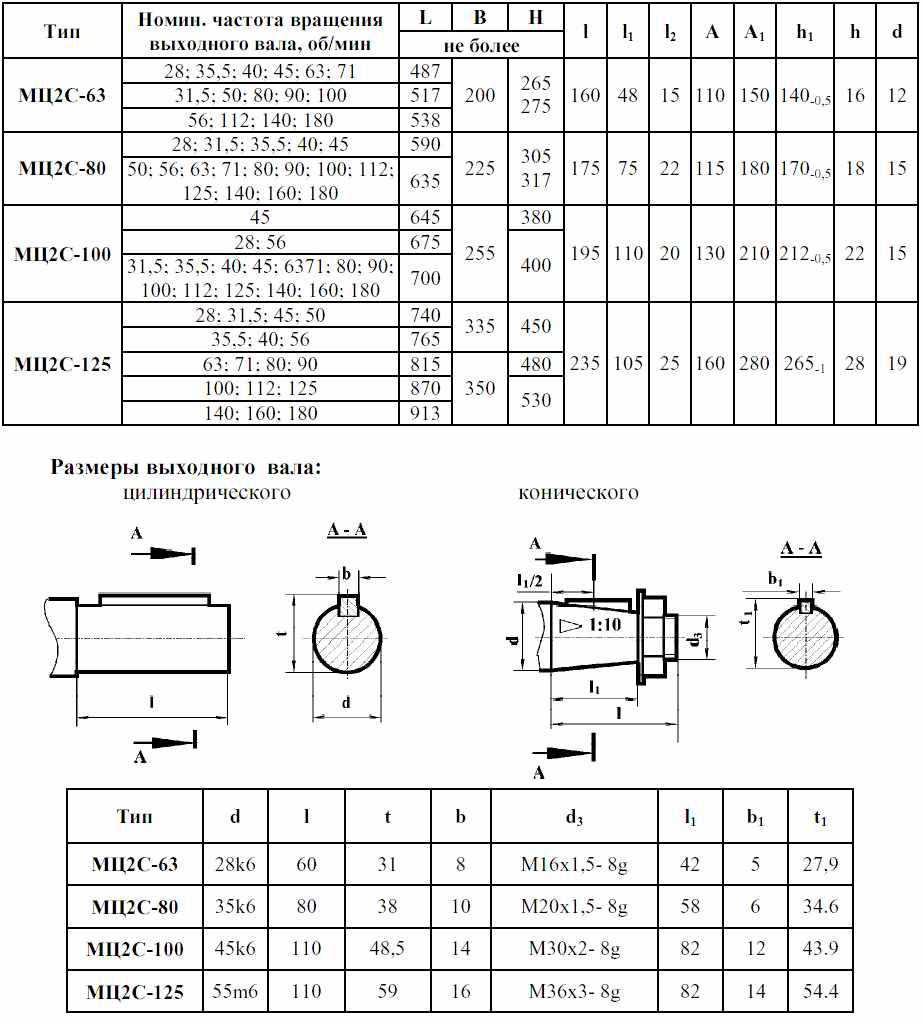

Coaxial helical gearmotor type: МЦ2С-63, МЦ2С-80, МЦ2С-100, МЦ2С-125

| Number of steps |

Two-stage |

|---|---|

| Axis arrangement |

Coaxial |

Further information on gearbox dimensions, shafts, gear ratios, etc. can be found in the catalogue.

Assignment

Cylindrical double-stage coaxial gearmotors type MC2C are

by general purpose electromechanical drives.

Conditions of use:

The gearmotors are designed for operation in operating mode S1

(according to GOST 183-74) with working time up to 24 h/day under the following conditions:

- output shaft rotation - in any direction;

- external environment - non-aggressive, non-explosive with content of non-conductive dust up to

10 mg/m3;

- climatic execution U (placement category 3) according to GOST 15150-69 when working on the

altitudes up to 1000 metres above sea level;

- gearmotors may be operated at an altitude of more than 1000 m above sea level when

compliance with the requirements of GOST 183-74;

- gearmotor motors are designed for AC mains operation with frequency of

50 Hz, nominal voltage 380 V. By agreement with the manufacturer it is allowed

manufacture of gearmotors for other standard voltages.

Example for writing down the gearmotor designation:

Motor - gearbox МЦ2С - 63 - 28 - 0,55 - G110 - Ц У3 , wherein

MC2C - gearmotor type;

63 - radius of location of satellite axes, mm;

28 - output shaft speed, rpm;

0,55 - electric motor power, kW;

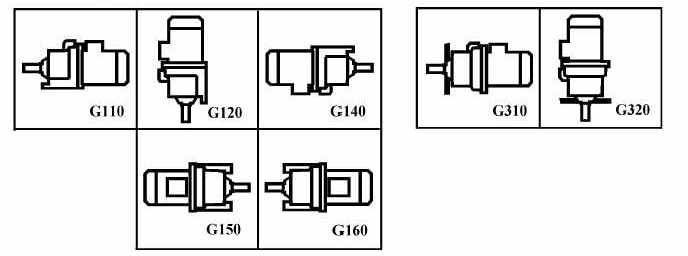

G110 - mounting version;

C output shaft (C - conical, C - cylindrical)

U3 - climatic version and placement category;

Structural design by mounting method.

|

Type

|

Nom. frequency

rotations shaft, rpm |

Rated torque

torque on the shaft, Nm |

Additional radial

shaft load, Н |

Weight without

grease, kg no more |

Power

engine, kW |

Motor efficiency

gearbox, at least |

| MC2C-63 |

28

|

175

|

3200

|

45

|

0,55

|

0,67

|

|

31,5

|

162

|

|||||

|

35,5

|

152

|

|||||

|

35,5

|

194

|

0,75

|

0,69

|

|||

|

40

|

171

|

|||||

|

45

|

156

|

|||||

|

50

|

190

|

|||||

|

50

|

190

|

1,1

|

0,73

|

|||

|

56

|

180

|

|||||

|

63

|

150

|

0,75

|

||||

|

71

|

148

|

|||||

|

80

|

160

|

1,5

|

0,77

|

|||

|

90

|

155

|

|||||

|

100

|

144

|

|||||

|

112

|

126

|

|||||

|

112

|

160

|

2,2

|

0,81

|

|||

|

125

|

159

|

|||||

|

140

|

147

|

|||||

|

160

|

128

|

|||||

|

180

|

116

|

|||||

|

180

|

140

|

3,0

|

0,82

|

|||

| MC2C-80 |

28

|

250

|

4300

|

75

|

0,75

|

0,71

|

|

28

|

357

|

1,1

|

0,74

|

|||

|

31,5

|

225

|

0,75

|

0,71

|

|||

|

31,5

|

321

|

1,1

|

0,74

|

|||

|

35,5

|

290

|

1,1

|

||||

|

40

|

264

|

1,1

|

||||

|

40

|

368

|

1,5

|

0,73

|

|||

|

45

|

221

|

1,1

|

0,74

|

|||

|

45

|

306

|

1,5

|

0,77

|

|||

|

50

|

200

|

1,1

|

0,74

|

|||

|

50

|

275

|

1,5

|

0,77

|

|||

|

50

|

403

|

2,2

|

0,80

|

|||

|

56

|

248

|

1,5

|

0,74

|

|||

|

56

|

364

|

2,2

|

0,80

|

|||

|

63

|

226

|

1,5

|

0,74

|

|||

|

63

|

331

|

2,2

|

0,80

|

|||

|

71

|

293

|

2,2

|

0,80

|

|||

|

71

|

407

|

3,0

|

0,90

|

|||

|

80

|

265

|

2,2

|

0,90

|

|||

|

80

|

366

|

3,0

|

0,80

|

|||

|

90

|

236

|

2,2

|

||||

|

90

|

301

|

3,0

|

||||

|

100

|

202

|

2,2

|

||||

|

100

|

275

|

3,0

|

||||

|

112

|

184

|

2,2

|

0,79

|

|||

|

112

|

252

|

3,0

|

0,80

|

|||

|

112

|

340

|

4,0

|

0,86

|

|||

|

125

|

219

|

3,0

|

0,80

|

|||

|

125

|

295

|

4,0

|

0,86

|

|||

|

140

|

270

|

4,0

|

||||

|

140

|

370

|

5,5

|

||||

|

160

|

247

|

4,0

|

||||

|

160

|

332

|

5,5

|

||||

|

180

|

289

|

4,0

|

||||

|

180

|

300

|

5,5

|

||||

| MC2C-100 |

28

|

741

|

6100

|

95

|

2,2

|

0,75

|

|

31,5

|

666

|

|||||

|

35,5

|

601

|

|||||

|

35,5

|

832

|

3,0

|

0,77

|

|||

|

40

|

689

|

|||||

|

45

|

632

|

|||||

|

45

|

817

|

4,0

|

0,78

|

|||

|

50

|

742

|

0,79

|

||||

|

56

|

677

|

0,78

|

||||

|

63

|

621

|

0,80

|

||||

|

63

|

826

|

5,5

|

0,88

|

|||

|

71

|

746

|

|||||

|

80

|

619

|

|||||

|

90

|

567

|

|||||

|

100

|

521

|

|||||

|

100

|

693

|

7,5

|

0,86

|

|||

|

112

|

617

|

|||||

|

125

|

554

|

|||||

|

140

|

500

|

|||||

|

160

|

454

|

|||||

|

180

|

380

|

|||||

| MC2C-125 |

28

|

971

|

7500

|

190

|

3,0

|

0,79

|

|

28

|

1043

|

4,0

|

0,80

|

|||

|

31,5

|

895

|

3,0

|

0,79

|

|||

|

31,5

|

1037

|

4,0

|

0,80

|

|||

|

35,5

|

1077

|

4,0

|

0,80

|

|||

|

40

|

958

|

4,0

|

0,80

|

|||

|

45

|

819

|

4,0

|

0,80

|

|||

|

45

|

1004

|

5,5

|

0,83

|

|||

|

50

|

756

|

4,0

|

0,80

|

|||

|

50

|

994

|

5,5

|

0,83

|

|||

|

56

|

884

|

5,5

|

0,83

|

|||

|

56

|

985

|

7,5

|

0,85

|

|||

|

63

|

827

|

5,5

|

0,82

|

|||

|

63

|

980

|

7,5

|

0,83

|

|||

|

71

|

1010

|

7,5

|

0,85

|

|||

|

80

|

874

|

7,5

|

0,85

|

|||

|

80

|

1080

|

11,0

|

0,86

|

|||

|

90

|

1104

|

11,0

|

0,86

|

|||

|

100

|

1021

|

11,0

|

0,86

|

|||

|

112

|

882

|

11,0

|

0,86

|

|||

|

112

|

925

|

15,0

|

0,86

|

|||

|

125

|

855

|

11,0

|

0,86

|

|||

|

160

|

1037

|

18,5

|

0,87

|

|||

|

180

|

959

|

18,5

|

0,87

|