Planetary gearmotor type: 4MP-25; 4MP-31,5; 4MP-40; 4MP-50; 4MP-63; 4MP-80; 4MP-100; 4MP-125

| Number of steps |

Single-stage ,Two-stage ,Three-stage |

|---|

Motor - planetary gearboxes 4MP are used in industry to increase torque in drilling rigs, screw and belt conveyors and other industrial applications.

Motor gearboxes 4MP has been manufactured by our company since 2012, during which time the gearbox design has been improved several times.

CNC machines and machining centres are used for machining of all parts. The drawings are finalised, the accuracy of meshing is improved, at the customer's request we grind the gear tooth, thus achieving the 6th class of accuracy. Maximum full contact of teeth is provided, which is typical for power gears. With maximum efficiency, the gearbox will provide the specified torque with minimum noise. In this regard, the wear resistance of these planetary gears is also at a high level

Thus, it can be confidently stated that this type of motor reducers is equal or superior in all parameters to its imported relatives from Europe, and the availability and ease of replacement of spare parts (maintainability) in almost any conditions makes them irreplaceable for the Russian industry. It is also worth noting that apart from the improved design, the production costs are also optimised, which makes the product cheaper and therefore more competitive.

Motor - planetary gearbox is designed for speed reduction and torque transmission to general machinery mechanisms (excluding load lifting mechanisms).

Motor - reducer is designed for continuous operation S1 according to GOST 183 (8-24 h/day) from AC mains with frequency 50 Hz or 60 Hz, rated voltage 220 and 380 V in the following conditions:

- the load is constant in value, of the same direction;

- output shaft rotation - in any direction without preference;

- external environment - non-aggressive, non-explosive with content of non-conductive dust up to 10 mg/m3;

Climatic execution according to GOST 15150:

U - temperate climate for categories 2 and 3.

Placement category 2 - operation in premises where temperature and humidity fluctuations are not significantly different from those in the open air, operating ambient temperature from minus 10°C to plus 45°C.

Placement category 3 - operation indoors, where temperature and humidity fluctuations are significantly less than outdoors, operating ambient temperature from minus 45°C to plus 40°C.

T - tropical climate for category 2.

UHL (moderately cold climate) and O for category 4 when operating at altitudes up to 1000 metres above sea level.

Example of a gearmotor designation when ordering:

4МП-50-28-1,5-G110-Ц-У3

where: 4MP - gearmotor type;

50 - radius of location of satellite axes, mm;

28 - nominal output shaft speed, rpm;

1.5 - power of the component electric motor, kW;

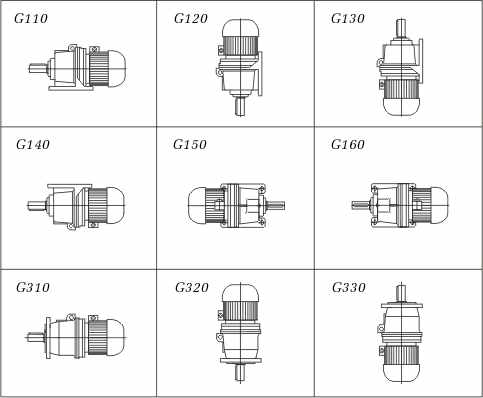

G110 - constructional design in terms of mounting method;

Ts - version of output shaft design;

U3 - climatic versions

Planetary gearmotors type 4MP |

|||||||||

|

Main technical characteristics of gearmotors 4MP-25 - 4MP-50

|

|||||||||

|

|

|||||||||

|

n, rpm |

4MP-25 gearmotor |

gear motor 4MP-31,5 |

gearmotor 4MP-40 |

gear motor 4MP-50 |

n,rpm |

||||

|

Mkr, N.m |

P, kW |

Mkr, N.m |

P, kW |

Mkr, N.m |

P, kW |

Mkr, N.m |

P, kW |

||

three-stage gearmotors |

|||||||||

|

3,55 |

90 |

0,12 |

230 |

0,18 |

375 |

0,18 |

459 |

0,18 |

3,55 |

|

638 |

0,25 |

||||||||

|

4,4 |

90 |

0,12 |

230 |

0,18 |

371 |

0,18 |

750 |

0,37 |

4,4 |

|

515 |

0,25 |

||||||||

|

5,6 |

90 |

0,12 |

230 |

0,18 |

375 |

0,25 |

750 |

0,55 |

5,6 |

|

598 |

0,37 |

||||||||

|

7,1 |

90 |

0,12 |

230 |

0,25 |

375 |

0,37 |

702 |

0,55 |

7,1 |

|

472 |

0,37 |

||||||||

|

9 |

90 |

0,12 |

230 |

0,25 |

372 |

0,37 |

750 |

0,75 |

9 |

|

554 |

0,55 |

||||||||

|

12,5 |

87 |

0,12 |

181 |

0,25 |

375 |

0,55 |

750 |

1,1 |

12,5 |

|

543 |

0,75 |

||||||||

|

16 |

68 |

0,12 |

209 |

0,37 |

311 |

0,55 |

623 |

1,1 |

16 |

|

425 |

0,75 |

||||||||

|

|

|||||||||

gearmotors two-stage |

|||||||||

|

18 |

62 |

0,12 |

190 |

0,37 |

375 |

0,75 |

750 |

1,5 |

18 |

|

129 |

0,25 |

283 |

0,55 |

565 |

1,1 |

||||

|

22,4 |

74 |

0,18 |

227 |

0,55 |

375 |

1,1 |

750 |

2,2 |

22,4 |

|

103 |

0,25 |

227 |

0,55 |

620 |

1,5 |

||||

|

28 |

83 |

0,25 |

182 |

0,55 |

364 |

1,1 |

727 |

2,2 |

28 |

|

122 |

0,37 |

248 |

0,75 |

496 |

1,5 |

||||

|

35,5 |

65 |

0,25 |

195 |

0,75 |

375 |

1,5 |

750 |

3 |

35,5 |

|

143 |

0,55 |

287 |

1,1 |

573 |

2,2 |

||||

|

45 |

76 |

0,37 |

154 |

0,75 |

308 |

1,5 |

617 |

3 |

45 |

|

113 |

0,55 |

226 |

1,1 |

452 |

2,2 |

||||

|

56 |

61 |

0,37 |

182 |

1,1 |

364 |

2,2 |

661 |

4 |

56 |

|

124 |

0,75 |

248 |

1,5 |

496 |

3 |

||||

|

71 |

72 |

0,55 |

195 |

1,5 |

375 |

3 |

717 |

5,5 |

71 |

|

143 |

1,1 |

287 |

2,2 |

521 |

4 |

||||

|

90 |

57 |

0,55 |

226 |

2,2 |

308 |

3 |

565 |

5,5 |

90 |

|

113 |

1,1 |

226 |

2,2 |

411 |

4 |

||||

|

|

|||||||||

gearmotors single-stage |

|||||||||

|

112 |

63 |

0,75 |

186 |

2,2 |

337 |

4 |

633 |

7,5 |

112 |

|

127 |

1,5 |

253 |

3 |

464 |

5,5 |

||||

|

140 |

74 |

1,1 |

202 |

3 |

371 |

5,5 |

742 |

11 |

140 |

|

148 |

2,2 |

270 |

4 |

506 |

7,5 |

||||

|

180 |

79 |

1,5 |

210 |

4 |

375 |

7,5 |

750 |

15 |

180 |

|

115 |

2,2 |

289 |

5,5 |

577 |

11 |

||||

|

224 |

63 |

1,5 |

169 |

4 |

316 |

7,5 |

633 |

15 |

224 |

|

127 |

3 |

232 |

5,5 |

464 |

11 |

||||

|

280 |

74 |

2,2 |

186 |

5,5 |

371 |

11 |

506 |

15 |

280 |

|

135 |

4 |

253 |

7,5 |

371 |

11 |

||||

|

|

|||||||||

|

n - nominal speed of output shaft, rpm; |

|||||||||

| Main technical characteristics of gearmotors 4MP-63 - 4MP-125 | |||||||||

| n, rpm |

gear motor4MP-63 |

gear motor4MP-80 |

gear motor4MP-100 |

gear motor4MP-125 |

n,rpm | ||||

| Mkr, N.m | P, kW | Mkr, N.m | P, kW | Mkr, N.m | P, kW | Mkr, N.m | P, kW | ||

gearmotors three-stage |

|||||||||

| 3,55 | 944 | 0,37 | 1914 | 0,75 | 3827 | 1,5 | 7655 | 3 | 3,55 |

| 1403 | 0,55 | 2807 | 1,1 | 5614 | 2,2 | ||||

| 4,4 | 762 | 0,37 | 1544 | 0,75 | 3088 | 1,5 | 6176 | 3 | 4,4 |

| 1132 | 0,55 | 2265 | 1,1 | 4529 | 2,2 | ||||

| 5,6 | 890 | 0,55 | 1779 | 1,1 | 3559 | 2,2 | 6470 | 4 | 5,6 |

| 1213 | 0,75 | 2426 | 1,5 | 4853 | 3 | ||||

| 7,1 | 957 | 0,75 | 1914 | 1,5 | 3827 | 3 | 7017 | 5,5 | 7,1 |

| 1403 | 1,1 | 2807 | 2,2 | 5103 | 4 | ||||

| 9 | 1107 | 1,1 | 2214 | 2,2 | 4026 | 4 | 7549 | 7,5 | 9 |

| 1510 | 1,5 | 3019 | 3 | 5536 | 5,5 | ||||

| 12,5 | 1087 | 1,5 | 2174 | 3 | 3986 | 5,5 | 7971 | 11 | 12,5 |

| 1594 | 2,2 | 2899 | 4 | 5435 | 7,5 | ||||

| 16 | 849 | 1,5 | 1698 | 3 | 3114 | 5,5 | 6228 | 11 | 16 |

| 1246 | 2,2 | 2265 | 4 | 4246 | 7,5 | ||||

gearmotors two-stage |

|||||||||

| 18 | 1131 | 2,2 | 2056 | 4 | 3855 | 7,5 | 7711 | 15 | 18 |

| 1542 | 3 | 2827 | 5,5 | 5655 | 11 | ||||

| 22,4 | 1239 | 3,0 | 2272 | 5,5 | 4544 | 11 | 9088 | 22 | 22,4 |

| 1652 | 4 | 3098 | 7,5 | 6196 | 15 | ||||

| 28 | 991 | 3,0 | 1818 | 5,5 | 3635 | 11 | 7270 | 22 | 28 |

| 1322 | 4 | 2478 | 7,5 | 4957 | 15 | ||||

| 35,5 | 1043 | 4,0 | 1955 | 7,5 | 3910 | 15 | 7819 | 30 | 35,5 |

| 1434 | 5,5 | 2867 | 11 | 5734 | 22 | ||||

| 45 | 1131 | 5,5 | 2262 | 11 | 4524 | 22 | 9253 | 45 | 45 |

| 1542 | 7,5 | 3084 | 15 | 6169 | 30 | ||||

| 56 | 909 | 5,5 | 1818 | 11 | 3635 | 22 | 7435 | 45 | 56 |

| 1239 | 7,5 | 2478 | 15 | 4957 | 30 | ||||

| 71 | 977 | 7,5 | 1955 | 15 | 3910 | 30 | 7168 | 55 | 71 |

| 1434 | 11 | 2867 | 22 | 5865 | 45 | ||||

90 |

771 |

7,5 |

1542 |

15 |

3084 |

30 |

5655 |

55 |

90 |

1131 |

11 |

2262 |

22 |

4627 |

45 |

||||

gearmotors single-stage |

|||||||||

| 112 | 1265 | 15,0 | 1856 | 22 | 3796 | 45 | 7592 | 90 | 112 |

| 1561 | 18,5 | 3121 | 37 | 6327 | 75 | ||||

| 140 | 1012 | 15,0 | 2025 | 30 | 3712 | 55 | 6074 | 90 | 140 |

| 1485 | 22 | 3037 | 45 | 5061 | 75 | ||||

| 180 | 1155 | 22,0 | 1942 | 37 | 3937 | 75 | 6928 | 132 | 180 |

| 1575 | 30 | 2887 | 55 | 5774 | 110 | ||||

| 224 | 1265 | 30,0 | 1898 | 45 | 3796 | 90 | 5567 | 132 | 224 |

| 1561 | 37 | 3163 | 75 | 4640 | 110 | ||||

| 280 | 1012 | 30,0 | 1518 | 45 | 3037 | 90 | 4454 | 132 | 280 |

| 1248 | 37 | 2531 | 75 | 3712 | 110 | ||||

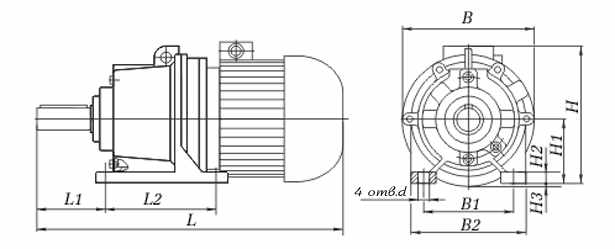

Overall and connecting dimensions of 4MP gearmotors on feet, mm.

| Designation gearmotor |

Rotational speed output, rpm |

L | B | H | L1 | L2 | B1 | B2 | H1 | H2 | H3 | d |

| No more | ||||||||||||

gear motor

|

3,55...16 | 397 | 150 | 160 | 63 | 110 | 120 | 150 | 80 | 12 | 12 | |

| 18...90 | 417 | 160 | 171 | |||||||||

| 112...280 | 478 | 200 | 205 | 20 | ||||||||

gear motor

|

3,55...16 | 460 | 190 | 215 | 82 | 130 | 155 | 190 | 100 | 15 | 15 | |

| 18...90 | 510 | 200 | 225 | |||||||||

| 112...280 | 590 | 250 | 247 | 25 | ||||||||

gear motor

|

3,55...16 | 500 | 224 | 247 | 110 | 170 | 180 | 220 | 112 | 20 | 20 | |

| 18...90 | 625 | 250 | 247 | |||||||||

| 112...280 | 725 | 350 | 305 | 63 | ||||||||

gear motor

|

3,55...16 | 637 | 270 | 295 | 145 | 210 | 220 | 265 | 132 | 22 | 22 | |

| 18...90 | 682 | 270 | 295 | |||||||||

| 112...280 | 925 | 350 | 360 | 43 | ||||||||

gear motor

|

3,55...16 | 652 | 350 | 345 | 110 | 140 | 260 | 325 | 160 | 32 | 24 | |

| 18...90 | 741 | 350 | 345 | |||||||||

| 112...280 | 960 | 400 | 440 | |||||||||

gear motor

|

3,55...16 | 810 | 380 | 400 | 175 | 325 | 320 | 380 | 200 | 40 | 35 | |

| 18...90 | 915 | 380 | 420 | |||||||||

| 112...280 | 1240 | 550 | 510 | 75 | ||||||||

gear motor

|

3,55...16 | 850 | 415 | 420 | 200 | 340 | 340 | 415 | 235 | 40 | 35 | |

| 18...90 | 1080 | 415 | 485 | |||||||||

| 112...280 | 1305 | 550 | 570 | 40 | ||||||||

gear motor

|

3,55...16 | 1070 | 500 | 540 | 270 | 380 | 400 | 500 | 275 | 50 | 42 | |

| 18...90 | 1360 | 535 | 570 | |||||||||

| 112...280 | 1415 | 590 | 630 | 20 | ||||||||

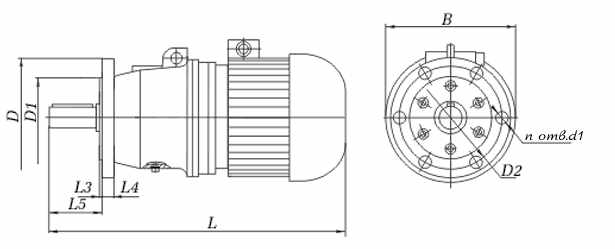

Overall and connection dimensions of 4MP gearmotors on flange, mm.

| Designation gearmotor |

Rotational speed output shaft, rpm |

L | B | L3 | L4 | L5 | D | D1 | D2 | d1 | n |

| No more | |||||||||||

gear motor

|

3,55...16 | 397 | 150 | 4 | 10 | 50 | 155 | 110 | 130 | 12 | 4 |

| 18...90 | 417 | 160 | |||||||||

| 112...280 | 478 | 200 | |||||||||

gear motor

|

3,55...16 | 460 | 190 | 5 | 12 | 68 | 180 | 130 | 155 | 12 | 6 |

| 18...90 | 510 | 200 | |||||||||

| 112...280 | 590 | 250 | |||||||||

gear motor

|

3,55...16 | 500 | 224 | 6 | 16 | 90 | 200 | 130 | 165 | 15 | 6 |

| 18...90 | 625 | 250 | |||||||||

| 112...280 | 725 | 350 | |||||||||

gear motor

|

3,55...16 | 637 | 270 | 8 | 18 | 124 | 250 | 180 | 215 | 17 | 6 |

| 18...90 | 682 | 270 | |||||||||

| 112...280 | 925 | 350 | |||||||||

gear motor

|

3,55...16 | 652 | 350 | 8 | 20 | 124 | 300 | 230 | 265 | 19 | 6 |

| 18...90 | 741 | 350 | |||||||||

| 112...280 | 960 | 400 | |||||||||

gear motor

|

3,55...16 | 810 | 400 | 10 | 22 | 152 | 400 | 320 | 350 | 22 | 6 |

| 18...90 | 915 | 400 | |||||||||

| 112...280 | 1240 | 550 | |||||||||

gear motor

|

3,55...16 | 850 | 500 | 14 | 28 | 180 | 500 | 400 | 450 | 22 | 8 |

| 18...90 | 1080 | 500 | |||||||||

| 112...280 | 1305 | 550 | |||||||||

gear motor

|

3,55...16 | 1070 | 600 | 18 | 35 | 245 | 600 | 480 | 540 | 26 | 8 |

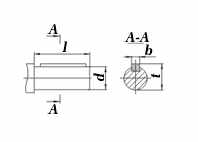

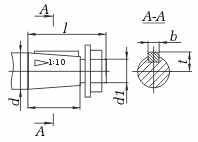

Design and dimensions of the output

Dimensions of cylindrical shafts |

Gearmotor | d | l | b | t |

| 4MP-25 | 25k6 | 42 | 8 | 28 | |

| 4MP-31.5 | 28k6 | 60 | 8 | 31 | |

| 4MP-40 | 35k6 | 80 | 10 | 38 | |

| 4MP-50 | 45k6 | 110 | 14 | 48,5 | |

| 4MP-63 | 55k6 | 110 | 16 | 59 | |

| 4MP-80 | 70k6 | 140 | 20 | 74,5 | |

| 4MP-100 | 80k6 | 160 | 22 | 85 | |

| 4MP-125 | 110k6 | 220 | 28 | 116 |

Dimensions of tapered shafts |

Gearmotor | d | d1 | l | l1 | b | t |

| 4MP-25 | 25 | M16x1.5 | 60 | 42 | 5 | 13,45 | |

| 4MP-31.5 | 28 | M16x1.5 | 60 | 42 | 5 | 14,95 | |

| 4MP-40 | 35 | M20x1.5 | 80 | 58 | 6 | 18,55 | |

| 4MP-50 | 45 | M30x2.0 | 110 | 82 | 12 | 23,45 | |

| 4MP-63 | 55 | M36x3.0 | 110 | 82 | 14 | 28,95 | |

| 4MP-80 | 70 | M48x3.0 | 140 | 105 | 18 | 36,38 | |

| 4MP-100 | 80 | M56x4.0 | 170 | 130 | 20 | 41,25 | |

| 4MP-125 | 110 | M80x4.0 | 210 | 165 | 25 | 55,88 |

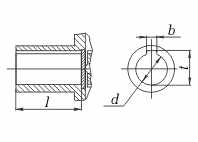

Dimensions of hollow shafts |

Gearmotor | d | l | b | t |

| 4MP-25 | customised | ||||

| 4MP-31.5 | 25Н7 | 55 | 8 | 28,1 | |

| 4MP-40 | 30Н7 | 70 | 8 | 33,1 | |

| 4MP-50 | 40Н7 | 80 | 12 | 43,3 | |

| 4MP-63 | customised | ||||

| 4MP-80 | customised | ||||

| 4MP-100 | customised | ||||

| 4MP-125 | customised | ||||

Design according to mounting method of 4MP gearmotors