Planetary gearmotor type: MPO1M-10, MPO2M-10, MPO2M-10, MPO2M-15, MPO2M-18

| Number of steps |

Single-stage |

|---|---|

| Axis arrangement |

Coaxial |

Assignment

Planetary gearmotors series MPO1M, MPO2M are designed for drives of mixing devices for chemical, medical, microbiological and other industries. They can also be used to drive general purpose machines.

Conditions of use:

- Gearmotors are designed for operation in S1 operating mode (according to GOST 183-74) with

- up to 24 hours per day;

- constant and variable load within the rated torque, single direction and reversible;

- rotation of the output shafts in any direction;

- external environment - non-aggressive, non-explosive with air dustiness not exceeding 10 mg/m3;

- climatic versions - U,T (placement category 3) according to GOST 15150 - 69 when working at an altitude of up to 1000 m above sea level;

- The gearmotor may be operated at an altitude of more than 1000 m above sea level provided that the requirements of GOST 183-74 are observed;

- Gearmotor motors are designed for operation from AC mains with frequency 50 Hz, nominal voltage 380 V. Gearmotors can be manufactured for other standard voltages upon agreement with the manufacturer.

Example for writing down the gearmotor designation:

Motor - reducer MPO1M-10 - VK- 5,74 -7,5 -250 - U3 , wherein

MPO1M - gearmotor type;

10 - nominal diameter of the driver;

VK - mounting version;

5.74 is the gear ratio;

7.5 - electric motor power, kW;

250 - output shaft speed;

U 3- climatic version and placement category;

Structural design by mounting method.

VC - vertical with support flange, output shaft downwards and annular groove on it for closed one

of the ring that transmits the axial forces;

F-2P - horizontal, flanged with half coupling;

Щ - horizontal on support legs;

F - horizontal with supporting flange;

B - vertical with support flange, output shaft downwards.

| Type | Execution by mounting |

Predatostochnoe number |

Frequency output rotation shaft, rpm |

Torque torque on the output shaft, Nm |

Maximum permissible torque at the time of the output shaft, Nm |

Maximum permissible radial cantilever load on the output shaft, kN |

Power, kW |

Mass, kg |

| Мотор-редуктор МПО-1М-10-5,74-7,5/250 | VK, F-2P | 5,74 | 250 | 278 | 430 | 1,5 | 7,5 | 150 |

| 250 | 278 | 7,5 | 200* | |||||

| Мотор-редуктор МПО-1М-10-5,74-5,5/250 | 250 | 205 | 5,5 | 125 | ||||

| 250 | 205 | 5,5 | 175 | |||||

| МПО-1М-10-5,74-3,0/250 | 250 | 110 | 3,0 | 105 | ||||

| 250 | 110 | 3,0 | 145* | |||||

| МПО-1М-10-5,74-5,5/170 | 170 | 290 | 5,5 | 150 | ||||

| 170 | 290 | 5,5 | 200* | |||||

| МПО-1М-10-5,74-3,0/170 | 170 | 160 | 3,0 | 125 | ||||

| 170 | 160 | 3,0 | 175* | |||||

| МПО-1М-10-5,74-5,5/195 | 7,34 | 195 | 260 | 5,5 | 125 | |||

| 5,5 | 175* | |||||||

| МПО-1М-10-5,74-3,0/195 | 140 | 3,0 | 105 | |||||

| 3,0 | 145* | |||||||

| МПО-1М-10-5,74-3,0/130 | 130 | 210 | 3,0 | 125 | ||||

| 3,0 | 175* | |||||||

| МПО-2М-10-23,1-3,0/63 | В

VC Ф Щ |

23,1 | 63 | 440 | 600 | 3,0 | 3,0 | 102 |

| 3,0 | 142* | |||||||

| МПО-2М-10-28,2-3,0/50 | 28,2 | 50 | 550 | 3,0 | 142* | |||

| 3,0 | 86 | |||||||

| МПО-2М-10-28,2-1,5/50 | 275 | 1,5 | 100* | |||||

| 1,5 | 81 | |||||||

| МПО-2М-10-28,2-0,75/50 | 140 | 0,75 | 88* | |||||

| 0,75 | 86 | |||||||

| МПО-2М-10-45,5-1,5/31,5 | 45,5 | 31,5 | 440 | 1,5 | 100* | |||

| 1,5 | 88 | |||||||

| МПО-2М-10-45,5-0,75/31,5 | 220 | 0,75 | 88* | |||||

| 220 | ||||||||

| 0,75 | 86 | |||||||

| МПО-2М-10-66,5-1,5/20 | 66,5 | 20 | 695 | 1,5 | 100* | |||

| 1,5 | 81 | |||||||

| МПО-2М-10-66,5-0,75/20 | 345 | 0,75 | 88* | |||||

| 0,75 | 81 | |||||||

| МПО-2М-10-81,6-0,75/16 | 81,6 | 16 | 435 | 0,75 | 88* | |||

| 0,75 | 71 | |||||||

| МПО-2М-10-208-0,37/6,3 | 208 | 6,3 | 545 | 0,37 | 85* | |||

| 0,37 | 71 | |||||||

| МПО-2М-10-2190-0,37/0,63 | 2190 | 0,63 | 5440 | 0,3 | 85* | |||

| 0,3 | 71 | |||||||

| MPO-2M-15-24,6-11/59 | 24,6 | 59 | 1730 | 2350 | 7,0

|

11 | 267 | |

| 11 | 315* | |||||||

| МПО-2М-15-24,6-7,5/59 | 1170 | 7,5 | 252 | |||||

| 7,5 | 305* | |||||||

| MPO-2M-15-32,1-11/45 | 32,1 | 45 | 2264 | 11 | 267 | |||

| 11 | 315* | |||||||

| МПО-2М-15-32,1-7,5/45 | 1545 | 7,5 | 252 | |||||

| 7,5 | 305* | |||||||

| МПО-2М-15-32,1-5,5/45 | 1130 | 5,5 | 228 | |||||

| МПО-2М-15-32,1-7,5/45 | 5,5 | 270* | ||||||

| МПО-2М-15-81,5-3,0/18 | 81,5 | 18 | 1545 | 3,0 | 207 | |||

| 3,0 | 260* | |||||||

| МПО-2М-15-101,7-1,5/14 | 101,7 | 14 | 990 | 1,5 | 191 | |||

| 1,5 | 204* | |||||||

| МПО-2М-15-204-0,75/6,7 | 204 | 6,7 | 1030 | 0,75 | 186 | |||

| 0,75 | 195* | |||||||

| МПО-2М-15-204-0,75/4,6 | 4,6 | 1510 | 0,75 | 190 | ||||

| МПО-2М-15-2469-0,55/56 | V, VK, F, S | 2469 | 0,56 | 12400 | 14000 | 0,55 | 186 | |

| 0,55 | 195* | |||||||

| MPO-2-18-22,8-15/64 | В

VC |

22,8 | 64 | 2177 | 4200 | 14,0 | 15 | 535 |

| 15 | 635* | |||||||

| MPO-2-18-29,6-15/49 | 29,6 | 49 | 2826 | 15 | 535 | |||

| 2826 | 15 | 635* | ||||||

| MPO-2-18- 29,6-11/49 | 2826 | 11 | 500 | |||||

| MPO-2-18-29,6-11/32 | 45,5 | 32 | 3186 | 11 | 500* | |||

| MPO-2-18-29,6-7,5/32 | 2172 | 7,5 | 485 | |||||

| MPO-2-18-66,5-7,5/22 | 66,5 | 22 | 3175 | 7,5 | 485* | |||

| MPO-2-18-66,5-5,5/22 | 2330 | 5,5 | 460 | |||||

| MPO-2-18-81,6-5,5/18 | 81,6 | 18 | 2856 | 5,5 | 460 | |||

| MPO-2-18-81,6-7,5/18 | 3896 | 7,5 | 485* |

* Explosion-proof electric motor

|

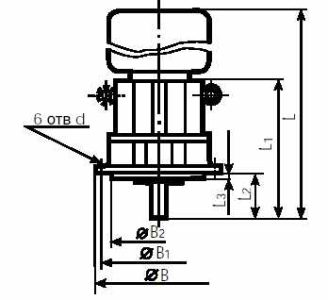

|

type

|

Mounting

fulfilment |

L

L1* |

L2

|

L3

|

B

|

B1

|

B2

|

d

|

| MPO1M-10 |

VC

|

850 max

590 min. |

110

|

6

|

330

|

300

|

270

|

13

|

| MPO1M-10 |

F-2P

|

775

|

130

|

6

|

330

|

300

|

270

|

17

|

| MPO2M-10 |

V, VK

|

420*

|

110

|

4

|

330

|

-

|

270

|

13

|

| MPO2M-15 |

V, VK

|

615*

|

190

|

6

|

420

|

375

|

330

|

22

|

| MPO2M-10 |

Ф

|

420*

|

110

|

6

|

330

|

300

|

270

|

13

|

| MPO2M-15 |

Ф

|

615*

|

190

|

10

|

420

|

-

|

330

|

22

|

| MPO2M-18 |

V, VK

|

1370max

|

220

|

-

|

520

|

471

|

470

|

22

|

*Length of gearbox part

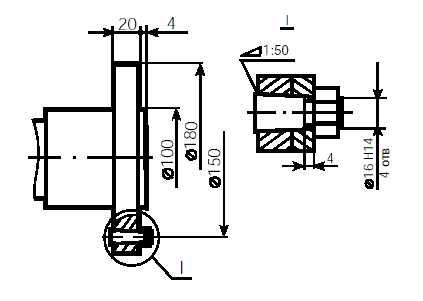

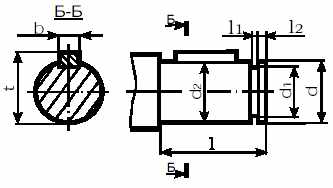

Dimensions of the output ends of the shafts:

- Cylindrical with annular groove

|

type

|

Mounting fulfilment |

I

|

I1

|

I2

|

d

|

d1

|

d2

|

b

|

t

|

| MPO1M-10 MPO2M-10 |

VC

|

80

|

5

|

4

|

38

|

32

|

40

|

12

|

43

|

| MPO2M-15 |

140

|

8

|

6

|

62

|

56

|

65

|

18

|

69

|

|

| MPO2M-18 |

170

|

10

|

8

|

78

|

70

|

80

|

22

|

85

|

- cylindrical

|

type

|

Mounting

fulfilment |

I

|

d

|

b

|

t

|

|

MPO2M-10

|

B, C, F

|

80

|

40

|

12

|

43

|

|

MPO2M-15

|

140

|

65

|

18

|

69

|

|

|

MPO2M-18

|

В

|

170

|

80

|

22

|

85

|

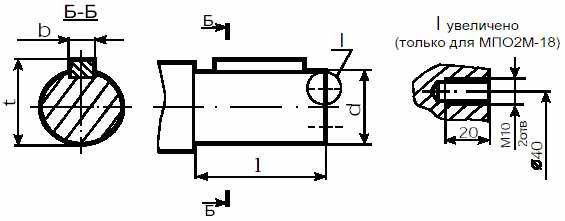

- with flanged coupling half (only for MPO1M-10 in F-2P version)