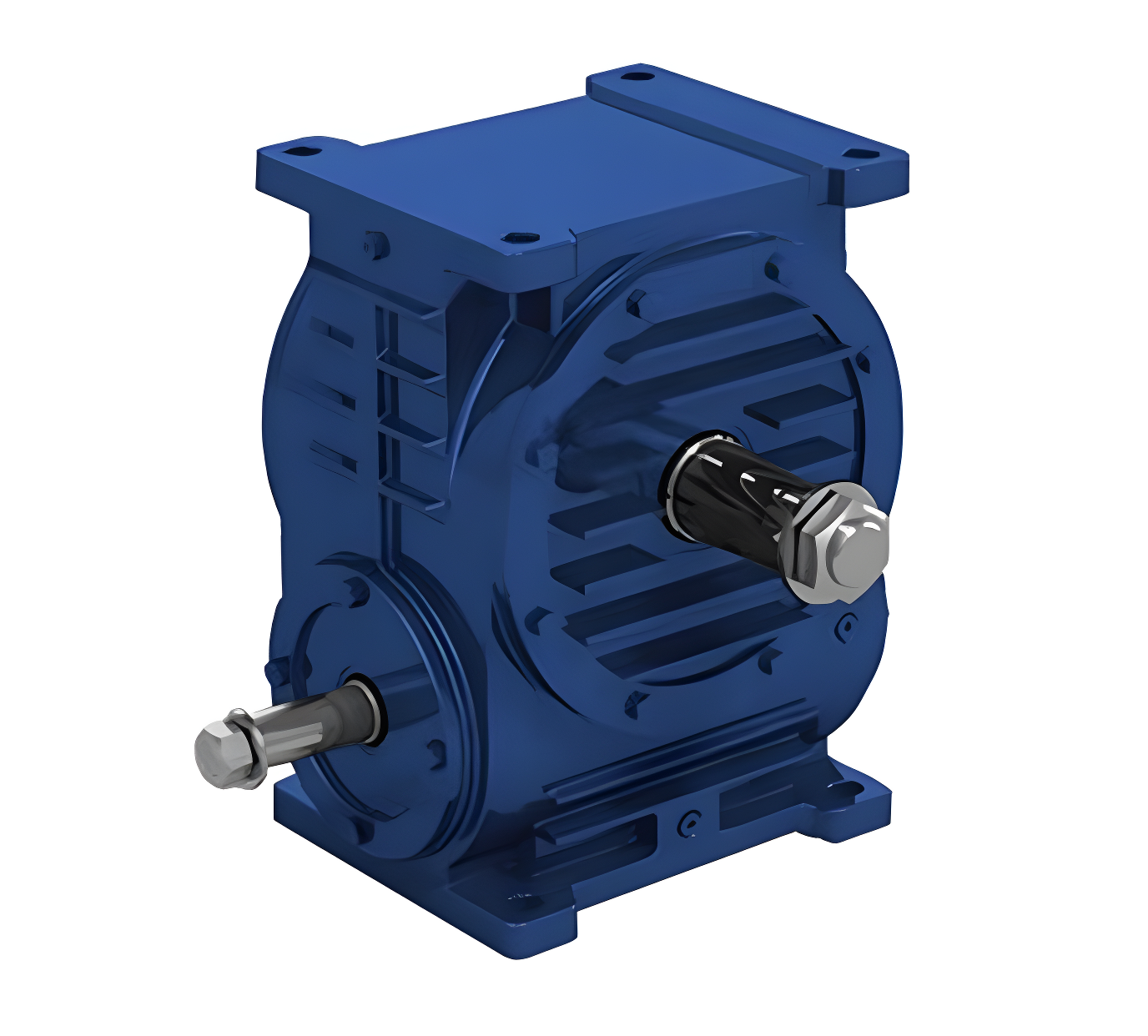

Worm gearboxes type Ch-100, Ch-125, Ch-160

from 52000 ₽

| Number of steps |

Single-stage |

|---|---|

| Axis arrangement |

Crossed |

Assignment

Universal single-stage worm gearboxes Ch-100, Ch-125, Ch-160 are designed to increase torque and reduce speed as components in drives of machines, equipment and mechanisms.

Examples of designation when ordering products

Gearbox Ch-100-40-51-1-KK-2VU-3, where:

H - gearbox type - single-stage worm gearbox;

100 is the centre distance;

40 is the nominal gear ratio;

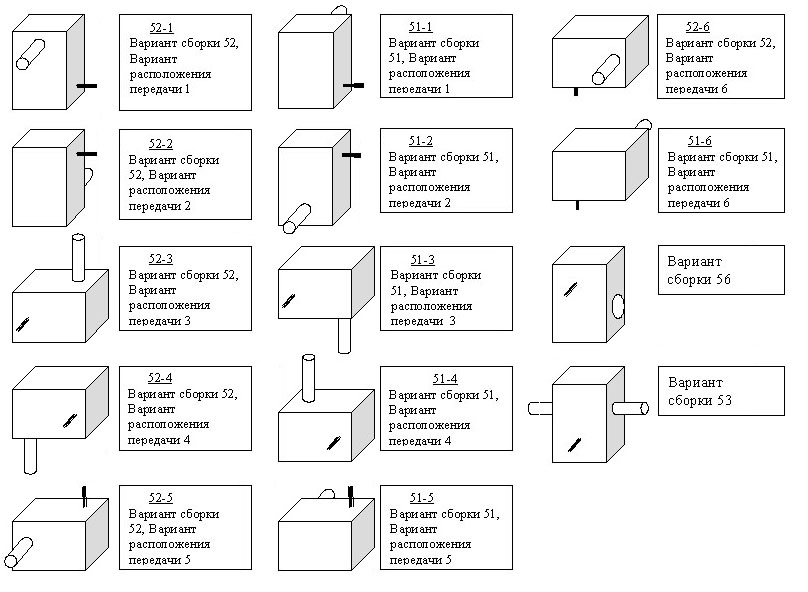

51 - assembly variant according to GOST 20373-94;

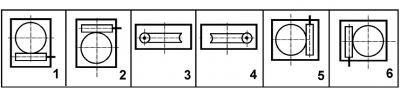

1 - variant of worm pair arrangement (worm under the wheel);

K - Variant design of high-speed shaft end - K - tapered with female thread

(Ts - cylindrical according to GOST 12080, K1 - conical with external thread according to GOST 12081);

K - Design variant of slow speed shaft end K - tapered with female thread

(Ts - cylindrical according to GOST 12080, K1 - conical with external thread according to GOST 12081);

2 - accuracy category according to GOST R 50891-96;

B - with fan;

- climatic versions U,T (for placement categories 1...3) and climatic versions UHL and O (for placement categories 4) according to GOST 15150-69.

Assembly options

Variation in the arrangement of the worm gear:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | aw | L | L1 | L2 | L3 | L4 | L5 | l | d | b | H | h |

| Ч-100 | 100 | 373 | 240 | 200 | 125 | 177 | 225 | 40 | 19 | 45 | 312 | 100 |

| Ч-125 | 125 | 437 | 275 | 230 | 146 | 210 | 261 | 45 | 19 | 60 | 396 | 111 |

| Ч-160 | 160 | 551 | 350 | 300 | 195 | 245 | 345 | 70 | 22 | 70 | 500 | 140 |

| Type | h1 | h2 | D | D2 | B | B1 | B2 | B3 | B4 | B5 | B6 | B7 |

| Ч-100 | 18 | 179 | 140 | 150 | 341 | 175 | 140 | 155 | 450 | 225 | 218 | 217 |

| Ч-125 | 22 | 217 | 165 | 170 | 363 | 230 | 190 | 135 | 460 | 230 | 246 | 242 |

| Ч-160 | 30 | 271 | 100 | 210 | 434 | 280 | 230 | 165 | 560 | 280 | 285 | 278 |

Shaft end dimensions:

- cylindrical

| Type | Shaft | l | b | d | t |

| Ч-100 |

in |

80 | 10 | 32 | 35 |

| Ч-125 | 80 | 10 | 32 | 35 | |

| Ч-160 | 110 | 12 | 40 | 43 | |

| Ч-100 | exits | 110 | 14 | 45 | 48,5 |

| Ч-125 | 110 | 16 | 55 | 59 | |

| Ч-160 | 140 | 20 | 70 | 74,5 |

- conical

| Type | Shaft | l | l1 | b | t | d | d3 |

| Ч-100 |

in |

80 | 58 | 6 | 17,05 | 35 | M20x1.5 |

| Ч-125 | 80 | 58 | 6 | 17,05 | 32 | M20x1.5 | |

| Ч-160 | 110 | 82 | 10 | 20,95 | 40 | M24x2 | |

| Ч-100 | exits | 110 | 82 | 12 | 23,45 | 45 | M30x2 |

| Ч-125 | 110 | 82 | 14 | 28,95 | 55 | M36x3 | |

| Ч-160 | 140 | 105 | 18 | 36,38 | 70 | M48x3 |

- hollow

| Type | L | L1 | L2 | Spline designation by

GOST 6033-80 |

d |

| Ч-100 | 205 | 90 | 57,5 | 45 x H7 x 2 | 46 |

| Ч-125 | 230 | 110 | 60 | 55 x H7 x 2.5 | 60 |

| Ч-160 | 275 | 130 | 72,5 | 70 x H7 x 2.5 | 72 |