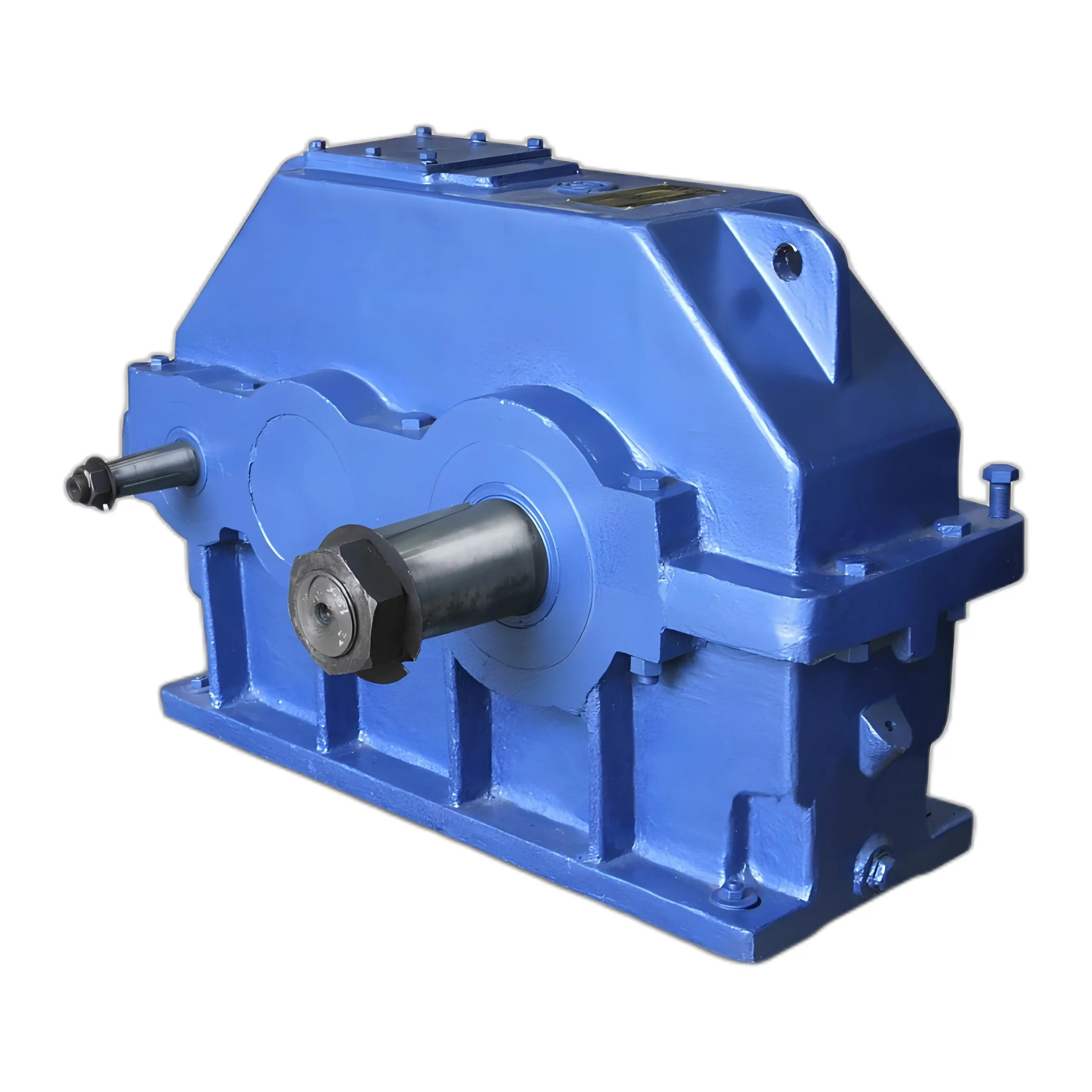

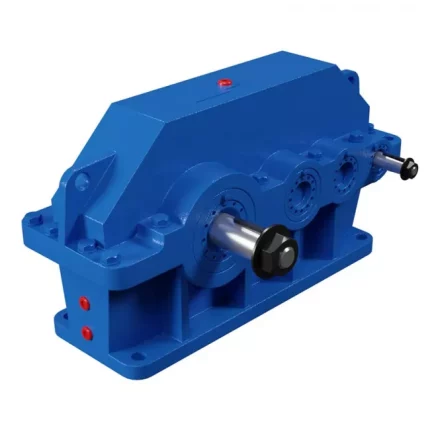

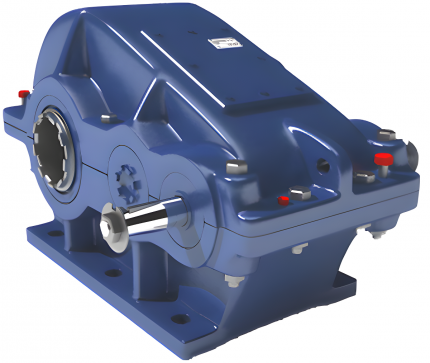

Two-stage gearboxes - Ts2U-100, Ts2U-125, Ts2U-160, Ts2U-200, Ts2U-250

from 35000 ₽

| Number of steps |

Two-stage |

|---|---|

| Axis arrangement |

Parallel |

Assignment

Ts2U gearboxes - These are new type gearboxes replacing older models such as RDC and RM.

Today they are used in various lifting and transport equipment, conveyor systems, truck cranes of Russian manufacturers, solovy systems of various directions.

IzhMSC plant offers a line of Ts2U gearboxes consisting of the following sizes: Ts2U-100 gearbox, Ts2U-125 gearbox, Ts2U-200 gearbox, Ts2U-250 gearbox.

Cylindrical two-stage horizontal gearboxes of general machine-building application of sizes Ts2U-100, Ts2U-125, Ts2U-200, Ts2U-250 are designed to change torques and speeds.

Conditions of application of cylindrical gearboxes Ts2U-100, Ts2U-125, Ts2U-200, Ts2U-250::

- constant and variable load, single direction and reversible;

- working for long periods of time or with intermittent stops;

- rotation of the shafts in any direction;

- the input shaft speed must not exceed 1800 rpm;

- ambient temperature from minus 40C to plus 50C;

- atmosphere of types I and II according to GOST 15150-69 at air dustiness not more than 10 mg / cubic metre;

- climatic versions U, T for placement categories 1...3 and climatic versions UHL and O for placement categories 4 according to GOST 15150-69

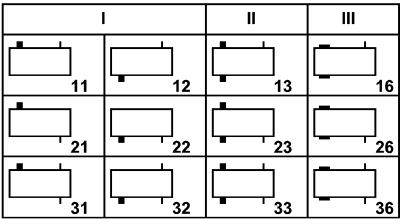

Assembly options:

І - with shaft ends under couplings,

as part of the gear coupling and with hollow output shaft of the 1Ts2U-250 gearbox;

ІІ - with ends for couplings;

ІІІ - with hollow output shaft of 1Ts2U-200 reducer

| Parameters | Size 1Ts2U | ||||||

| 100 | 125 | 160 | 200 | 250 | |||

| Nominal gear ratios | 8; 10; 12,5; 16; 20; 25; 31,5; 40 | ||||||

| Rated torque at output shaft during continuous operation with constant load, Nm | continuous (H) SP=100% | 315 | 630 | 1250 | 2500 | 5000 | |

| Rated output torque at the output shaft during repeated-short-time operation, Nm | heavy (T) SP=40% | 315 | 630 | 1600 | 3150 | 6300 | |

| medium (C) SP=25% | 2000 | 4000 | 8000 | ||||

| light (L)

SP=15% |

2500 | 5000 | 10000 | ||||

| Permissible radial cantilever load applied at the centre of the shaft seating,

Н |

input | continuous (H) SP=100% | 500 | 750 | 1000 | 2240 | 3150 |

| heavy (T) SP=40% | 1150 | 2500 | 3550 | ||||

| medium (C) SP=25% | 1280 | 2800 | 4000 | ||||

| light (L)

SP=15% |

1450 | 3150 | 4500 | ||||

| output | continuous(H) SP=100% | 4500 | 6300 | 9000 | 12500 | 18000 | |

| heavy (T) SP=40% | 10000 | 14000 | 20000 | ||||

| medium (C) SP=25% | 11200 | 16000 | 22400 | ||||

| light (L)

SP=15% |

12500 | 18000 | 25000 | ||||

| efficiency, at least | 0,97 | ||||||

| Weight, kg | cast-iron | 37 | 55 | 95 | 170 | 310 | |

| aluminium-clad | 21 | 31,5 | 57 | - | - | ||

Notes:

- values of permissible torques and radial cantilever loads of 1Ts2U-160, 1Ts2U-200, 1Ts2U-250 gearboxes with gear ratios 8, 10, 12,5 at light duty, 1Ts2U-200 gearboxes with cylindrical end of output shaft should be reduced by 20%;

- the nominal radial load on the output shaft for assembly variants 13, 23, 33 and on the input shaft for 31, 32, 33 must be halved;

- The permissible torques at the output shaft must be reduced by 30% when the gearboxes are operated in reverse.

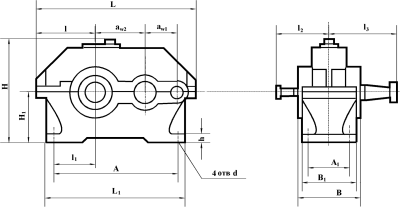

| Type | аw2 | aw1 | L | L1 | 1 | 11 | l2 | l3 | Н | H1 | A | A1 | d | B | B1 | h | |

| no more | Cast iron housing | Aluminium housing | |||||||||||||||

| 1TS2U-100 | 100 | 80 | 390 | 325 | 136 | 85 | 136 | 165 | 230 | 112 | 290 | 109 | 15 | 155 | 145 | - | 20±3 |

| 1TS2U-125 | 125 | 80 | 446 | 375 | 160 | 106 | 145 | 206 | 272 | 132 | 335 | 125 | 19 | 175 | 165 | - | 22±3 |

| 1TS2U-160 | 160 | 100 | 557 | 475 | 200 | 135 | 170 | 224 | 345 | 170 | 425 | 140 | 24 | 206 | 195 | 24±4 | 28±4 |

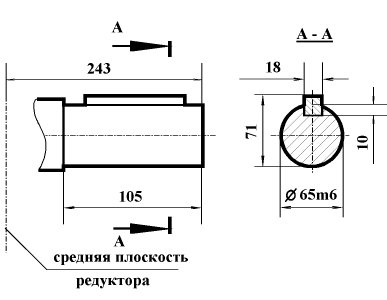

| 1TS2U-200 | 200 | 125 | 678 | 580 | 243 | 165 | 212 | 280 | 425 | 212 | 515 | 165 | 24 | 243 | 230 | 30±4 | - |

| 1TS2U-250 | 250 | 160 | 829 | 730 | 290 | 212 | 265 | 335 | 530 | 265 | 670 | 218 | 28 | 290 | 280 | 32±4 | - |

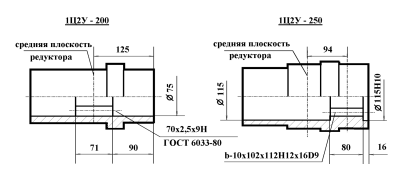

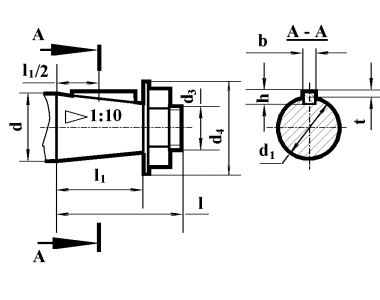

Dimensions of input and output shaft ends

(customised shaft ends are available).

| Type | Shaft | d | d1 | d3 | d4,

no more |

l | l1 | b | h | t |

| 1TS2U-100 | in | 20 | 18,2 | M12x1,25 | 40 | 50 | 36 | 4 | 4 | 2,5 |

| 1TS2U-125 | 20 | 18,2 | M12x1,25 | 40 | 50 | 36 | 4 | 4 | 2,5 | |

| 1TS2U-160 | 25 | 22,9 | M16x1,5 | 45 | 60 | 42 | 5 | 5 | 3,0 | |

| 1TS2U-200 | 30 | 27,1 | M20x1.5 | 50 | 80 | 58 | 5 | 5 | 3,0 | |

| 1TS2U-250 | 40 | 35,9 | M24x2,0 | 63 | 110 | 82 | 10 | 8 | 5,0 | |

| 1TS2U-100 | exits | 35 | 32,10 | M20x1.5 | 50 | 80 | 58 | 6 | 6 | 3,5 |

| 1TS2U-125 | 45 | 40,90 | M30x2,0 | 75 | 110 | 82 | 12 | 8 | 5,0 | |

| 1TS2U-160 | 55 | 50,90 | M36x3,0 | 88 | 110 | 82 | 14 | 9 | 5,5 | |

| 1TS2U-200 | 70 | 64,75 | M48x3,0 | 100 | 140 | 105 | 18 | 11 | 7,0 | |

| 1TS2U-250 | 90 | 83,50 | M64x4,0 | 130 | 170 | 130 | 22 | 14 | 9,0 |

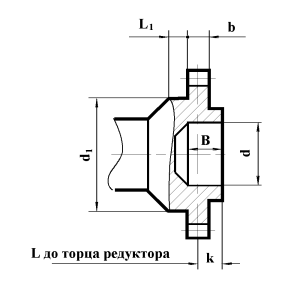

Dimensions of the output shaft ends:

- toothed coupling

| Type | m | z | b | L | L1

at least |

k | В | d | d1 |

| 1TS2U-160 | 4 | 40 | 20 | 48 | 20 | 19 | 38 | 72 F7 | 95 F7 |

| 1TS2U-200 | 5 | 40 | 25 | 55 | 32 | 22 | 50 | 80 F7 | 105 F7 |

| 1TS2U-250 | 4 | 56 | 35 | 63 | 16 | 31 | 50 | 120 F8 | 170 F7 |

- hollow shafts

- of cylindrical end of output shaft 1Ts2U - 200